The History and Evolution of Laser Engraving and Marking Machines

Laser technology has become an essential part of modern manufacturing, enabling precise and permanent product identification across industries. From simple lab experiments to today’s advanced laser engraving and laser marking machines, this technology has come a long way. In this blog, we explore the history and evolution of laser engraving and marking machines, how they work, and why they are critical in industries today.

Who Invented the Laser Engraver?

The roots of laser engraving trace back to the invention of the laser itself in 1960 by Theodore H. Maiman. While he didn’t invent laser engraving directly, his creation of the first working laser laid the foundation for all laser-based technologies.

By the late 1960s and early 1970s, researchers began exploring the potential of lasers for material processing. Laser engraving and marking slowly emerged as viable applications, especially for industrial purposes where precision and durability were crucial.

Over the decades, improvements in laser control systems, beam focusing, and automation turned the laser engraver from a research tool into a staple of modern manufacturing.

Understanding Laser Engraving and Marking

To appreciate how far this technology has come, let’s first define two essential processes: laser engraving and laser marking.

Laser Engraving

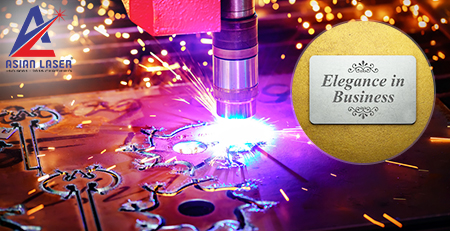

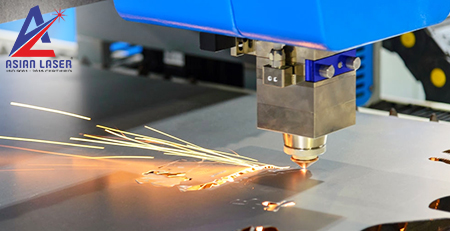

Laser engraving involves removing material from the surface to create deep, visible marks. It’s ideal for serial numbers, text, and graphics on metal, plastic, or wood. The result is permanent and resistant to wear, making it perfect for branding and traceability.

Laser Marking

Laser marking is a broader process that includes techniques like annealing, foaming, carbon migration, and color change. Unlike engraving, marking doesn’t remove material. Instead, it alters the material’s surface properties to create visible contrasts.

Laser Etching vs. Laser Engraving: What’s the Difference?

These two terms are often used interchangeably, but they’re technically different:

- Laser Etching is a subset of engraving, where the laser melts the surface to create a shallow, raised mark. It’s faster than engraving but not as deep or durable.

- Laser Engraving vaporizes the material to carve into it, producing deeper and more durable marks.

Understanding this difference helps industries select the best method for their application—whether it’s decorative marking, serializing parts, or high-precision branding.

The Evolution of Laser Marking Machines

Laser technology has rapidly advanced since its inception. Here’s a brief look at the timeline:

1960s–1970s: Early Laser Experiments

Lasers were still in the experimental stage. Marking and engraving were not yet commercialized, but the groundwork was laid.

1980s: Industrial Adoption Begins

The first commercial laser marking systems entered the market, mostly used in aerospace and defense industries for marking metal parts.

1990s: Rise of Fiber Lasers

Fiber laser technology emerged, offering better efficiency, lower maintenance, and higher speeds. This was a game-changer for industries like automotive and electronics.

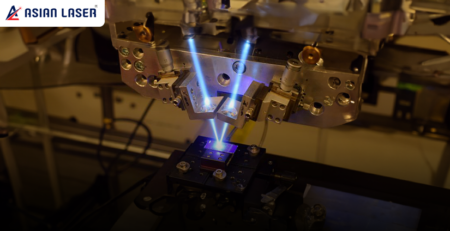

2000s–2010s: Software & Automation Integration

Laser systems became more intelligent. With advanced CAD/CAM software, automation, and integrated vision systems, laser machines offered better precision and traceability.

Today: Smart, Compact, and Versatile Machines

Modern laser engraving and laser marking machines are compact, high-speed, and user-friendly. With support for multiple materials, cloud-based control, and AI integration, these machines are now indispensable in manufacturing.

Laser Technology in Modern Industry

Today, laser systems are used across various industries for tasks like:

- Part identification in automotive and aerospace

- Medical tool marking for traceability

- Electronics labeling

- Branding in packaging and FMCG sectors

- Jewelry engraving and personalization

These applications demand high reliability, consistency, and speed—all of which laser systems provide.

The Role of Laser Engraving Machines in India’s Growth

India’s manufacturing sector has witnessed significant growth in recent years, with a rising demand for laser engraving and laser marking machines. From small businesses to large-scale manufacturers, everyone is embracing laser technology to meet quality, compliance, and branding standards.

At Asian Laser, we are proud to contribute to this transformation by offering state-of-the-art laser machines built for Indian industries.

Expanding Horizons: Industrial Laser Welding Machine Manufacturers in India

The evolution doesn’t stop at marking and engraving. Laser technology has also revolutionized welding, especially for intricate, high-precision jobs. As leading industrial laser welding machine manufacturers in India, we’re expanding our product portfolio to meet this growing demand.

Laser welding offers:

- High-precision joins with minimal heat distortion

- Cleaner, stronger welds

- Faster production cycles

It’s the future of industrial fabrication, and we’re here to power it.

Conclusion: From Invention to Innovation

From the first ruby laser in 1960 to today’s fully automated engraving systems, the history of laser engraving and marking is a story of constant innovation. These machines have evolved into must-have tools for industries seeking speed, precision, and permanence.

At Asian Laser, we’re proud to be part of this journey, offering cutting-edge laser engraving, laser marking, and laser welding machines tailored for Indian industries. As one of the trusted laser marking and industrial laser welding machine manufacturers in India, we continue to deliver reliable solutions to power your business forward.

Ready to upgrade your marking and welding process? Contact us today for expert guidance and a custom solution.

Frequently Asked Questions (FAQs)

-

- Who invented the laser engraver?

Laser engraving evolved from the invention of the laser by Theodore H. Maiman in 1960, and was later adapted for industrial marking applications. - What is the difference between laser etching and laser engraving?

Laser etching creates shallow marks by melting the surface, while laser engraving removes material to create deeper, more permanent marks. - What are laser marking machines used for?

Laser marking machines are used to add serial numbers, barcodes, logos, and other identifiers on metals, plastics, and various other materials. - How have laser engraving machines evolved over time?

They’ve evolved from basic lab tools to high-speed, software-integrated machines with applications in modern manufacturing, branding, and traceability. - Are laser welding machines related to laser marking technology?

Yes, both use laser beams for precision processing—marking alters surfaces for identification, while welding fuses materials for high-strength bonding.

- Who invented the laser engraver?