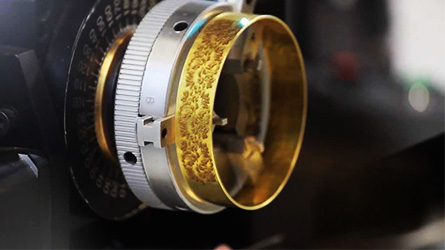

Jewellery Marking

By streamlining the process, jewellery laser machines help make manufacturing precise and faster.

The accuracy of laser machines makes working around heat-sensitive jewels and components of complex geometries easy, and there is no need for time-consuming products or post-processing.

The thinness of the laser beam prevents discoloration of the surrounding metals and makes the work appear seamless.

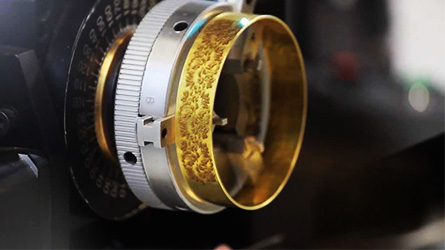

Jewellery Welding.

By streamlining the process, jewellery laser machines help make manufacturing precise and faster.

The accuracy of laser machines makes working around heat-sensitive jewels and components of complex geometries easy, and there is no need for time-consuming products or post-processing.

The thinness of the laser beam prevents discoloration of the surrounding metals and makes the work appear seamless.

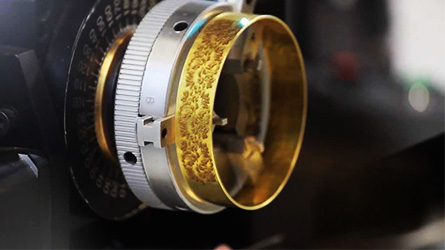

Jewellery Marking

By streamlining the process, jewellery laser machines help make manufacturing precise and faster.

The accuracy of laser machines makes working around heat-sensitive jewels and components of complex geometries easy, and there is no need for time-consuming products or post-processing.

The thinness of the laser beam prevents discoloration of the surrounding metals and makes the work appear seamless.

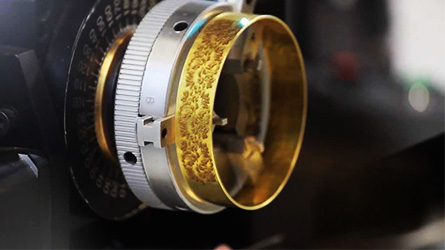

JewelleryWelding.

By streamlining the process, jewellery laser machines help make manufacturing precise and faster.

The accuracy of laser machines makes working around heat-sensitive jewels and components of complex geometries easy, and there is no need for time-consuming products or post-processing.

The thinness of the laser beam prevents discoloration of the surrounding metals and makes the work appear seamless.

Hallmarking

Laser machines are suitable for more substantial marks on finished or semi-finished hallmarking components, mainly where a display or feature mark is used. It can be used on money clips, key-rings, and silver giftware as it is likely to produce a feature mark without any bruising or distortion at accurately the required size, position, and depth.

Watch

In the world of horology, the application for laser technology varies according to the hurdles in this industry. The weld joints that make up the straps and various components of the watches are profoundly stressable and optically appearing. Clean cutting areas, flexible contour guiding, and permanent markings can be done faster on watches than traditional methods.

Watch

In the world of horology, the application for laser technology vary according to the hurdles in this industry. The weld joints that make up the straps and various components of the watches are profoundly stressable and optically appearing. Clean cutting areas, flexible contour guiding, and permanent markings can be done faster on watches than traditional methods.

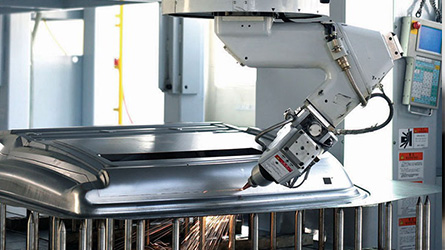

Automobiles

Laser machines have been playing a significant role in the automotive industry for a long time.

If a high level of automation, low costs, and flexibility are essential for the production process, laser systems are an optimal choice.

The laser machines have notable advantages compared to traditional processing methods.

Therefore, multiple car parts are welded, cut, or marked by laser machines.

Healthcare

Thanks to its distinctive qualities, like precision and flexibility, laser machines are the first choice in medical technology and have become an integral production tool. Whether it is an endoscope, a medical instrument, or an implant, medical technology products are produced with lasers. Laser systems are ideally suited for welding, cutting, and labelling all common materials.

Healthcare

Thanks to its distinctive qualities, like precision and flexibility, laser machines are the first choice in medical technology and have become an integral production tool. Whether it is an endoscope, a medical instrument, or an implant, medical technology products are produced with lasers. Laser systems are ideally suited for welding, cutting, and labelling all common materials.

Stainless Steel

Whether it is creating or repairing steel products, laser machines are optimal in the many ways of mould making. It could be adjusting contours or modifying the surface geometry of moulding steel tools.

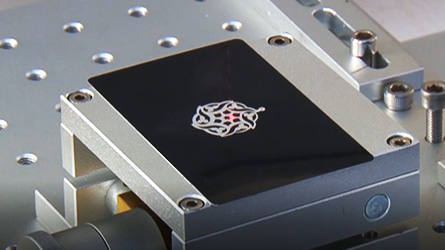

Electronics

Nowadays, laser applications are an integral part of the electronics industry. Lasers weld, cut, and label all sorts of parts, components, and end products consisting of different materials. In terms of speed and precision, the laser has significant advantages compared to conventional techniques and offers the user new processing options all the time.

Electronics

Nowadays, laser applications are an integral part of the electronics industry. Lasers weld, cut, and label all sorts of parts, components, and end products consisting of different materials. In terms of speed and precision, the laser has significant advantages compared to conventional techniques and offers the user new processing options all the time.