How can lasers machines help fight counterfeiting?

Supply chains are not furnished in terms of their ability to protect and identify the penetration of unsecured counterfeit goods. With today’s multiple supply chains and to make counterfeit products in one country and sell them in another, the solutions to counter the growing counterfeit problem needs to be global. The global solution to the counterfeit problem starts with a foundational layer of globally accepted supply chain standards, which act as building blocks. According to research, the use of standards-based Automatic Identification and Data Capture (AIDC), i.e., in barcodes or RFID tags, is to identify objects and seize the data about them at cutting points in the supply chain.

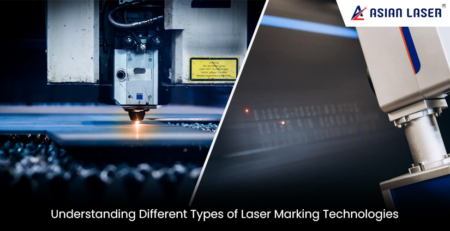

Widely accepted anti-counterfeit technologies approach has enabled the industry to devise different mechanisms that prevent and detect counterfeiting, piracy, and smuggling. The goal of an anti-counterfeit technology is to allow the authentication of an item, by government, industry, regulators, and consumers through track and trace and establishing a chain of custody and ownership. The secondary purpose may be to act as a deterrent against counterfeiting a product, considering the difficulty or cost involved in the likelihood of detection, and therefore prosecution. The majority of laser solutions can be completed on one or more of the packaging levels; some can even be applied at the product level but entail substantial costs of implementation.

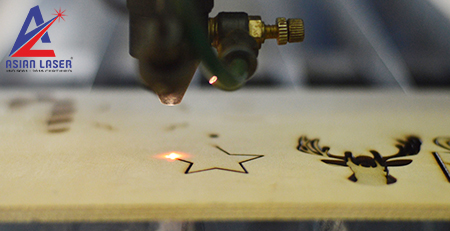

There are several ways to fight with counterfeit, which includes comparing elements to online databases. But perhaps no anti-counterfeiting device is more immediate and tangible than the engraving of genuine parts with different and identifiable marks.

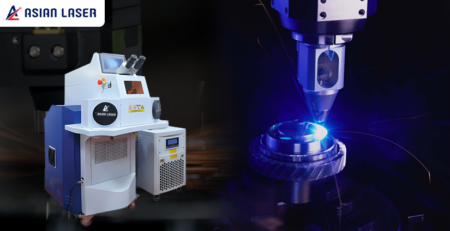

One of the most valuable forms of laser engraving is the capacity to lastingly add a name, serial number, company logo, or other identifying mark to just about any type of material imaginable. It includes various materials commonly used in laser production. Thanks to the high resolution of Asian Laser systems, our high-quality marks can be made within the least dimension parameters. It’s likely to mark everything from a corporate-supplied cell phone to laptop or PCB boards, silicon wafers, and semiconductor parts.

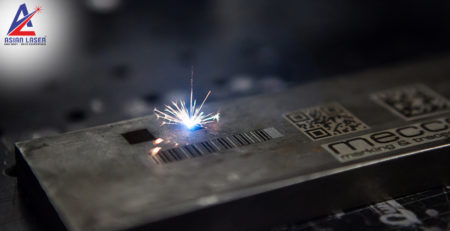

In addition to customizable branding, Asian Laser systems also support unique identification codes in the form of bar codes, data matrix codes, and human-readable text. These are required for identification, traceability, and accountability of government property purchases, and can be implemented immediately either to an individual part or a non-removable tag affixed to an item. According to research, markings are the standard indicator that a product meets the requirements mandated for an extensive range of product families, including electronics.

Counterfeiting is an insidious difficulty in today’s manufacturing panorama, and no single tool can inscribe all of its facets. But the initiation of a laser system at any stage can design an elegant and cost-effective solution that will go a long way toward making possessions more reliable, elements more trustworthy, and businesses more stable. Moreover, the right integration of the system represents an essential step toward a more competitive world.

To gain more information on using a laser machine to design marks, contact us to set up an induction with the distributor in your area.