Why Jewellery Manufacturers are Switching to Laser Welding Machines?

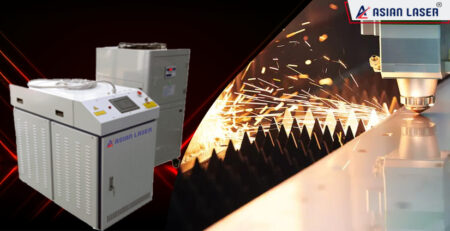

The laser welding machine manufacturers in India, in particular, are at the forefront of assisting jewellers in modernizing their operations. As traditional methods become increasingly limited, firms are turning to new technologies to improve productivity, precision, and product quality.

Laser welding machine manufacturers across the country are experiencing increased demand from jewellers who require better, quicker, and more precise instruments to stay competitive. Machines such as the jewellery laser welding machine are becoming increasingly important in large and small businesses as equipment prices fall. In this essay, we will look at the primary reasons for this movement, compare pricing trends (including the jewellery laser welding equipment price in India), and discuss how this innovation is transforming the industry.

Traditional Techniques: Time-Consuming and Limited

In the past, jewellery-making has mostly involved hand soldering using flow and blow torches. Both years of experience and deft hands are necessary for these methods. Although they have good art, they have certain disadvantages:

- The risk of damaging heat-sensitive stones is high.

- Limited precision with small or complicated designs.

- Labour-intensive and slow procedures

- Inconsistent joint strength

As consumer expectations for quality and turnaround time increase, these limitations are no longer sustainable for many manufacturers.

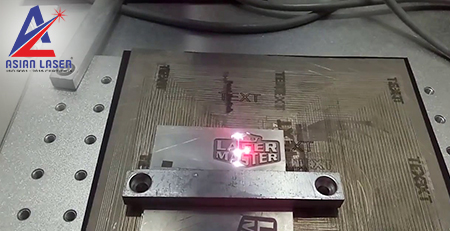

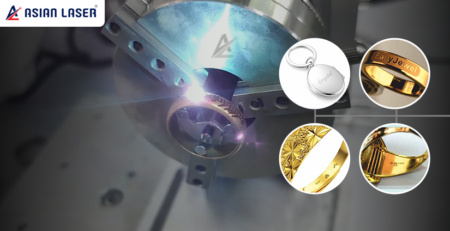

Laser Welding: The Future of Jewellery Crafting

A jeweller laser welding machine connects metals with outstanding quality using an intensely concentrated laser stream. With the use of this technology, jewellers may microweld without affecting the stones or around material. The outcome? High durability, little metal loss, and clean, almost undetectable joints.

Laser welding is ideal for tasks like:

- Chain repairs

- Ring resizing

- Retipping prongs

- Fixing porous castings

- Assembling intricate pieces

Key Benefits Driving the Shift

1. Unmatched Precision

Traditional welding processes cannot compete with a laser’s accuracy. Because the structure is only a few microns in diameter, even the smallest surfaces may be properly joined. This is particularly valuable in diamond settings, filigree work, and detailed repairs.

2. Speed and Productivity

Laser welding improves production efficiency by removing stages such as fluxing and post-weld polishing.

3. Enhanced Durability and Finish

Laser welds are stronger and more uniform. There is no contamination from welding metals because the original metal has been fused. The finish is smooth and requires little or no additional work.

4. Minimal Heat Distortion

The accuracy of the structure minimizes heat distribution, protecting gemstones and reducing warping in delicate objects.

5. Lower Long-Term Costs

Even though the cost of a Jewellery laser welding machine in India may be high up front, it is worthwhile because:

- Decreased wasting of materials

- Fewer errors and reworks

- Reduced reliance on labor

- Reduced production cycles

Market Trends: Increasing Accessibility

As more manufacturers enter the market, laser welding machine manufacturers in India lower the cost and accessibility of the technology. The current price of a jewellery welding machine varies according to its features, power, and brand. Here’s a quick summary:

|

Machine Type |

Typical Price Range (INR) |

Features |

||

| Entry-level Laser Welder |

₹4.5 lakhs onwards |

Suitable for basic repairs and small workshops |

||

| Mid-range Laser Welder |

₹5.5 lakhs onwards |

Better optics, precision control, more power |

||

| High-end Laser Welder |

₹12 lakhs onwards |

Advanced touchscreen interfaces, |

As demand grows, jewellery laser machine price points are becoming more competitive, especially with government incentives and financing options for small businesses.

Comparison Table: Laser Welding vs. Traditional Soldering

|

Feature |

Traditional Soldering |

Laser Welding |

|

|

Heat Control |

Low |

Very High |

|

|

Damage to Stones |

High Risk | Minimal Risk | |

|

Time per Repair |

20–30 min |

3–5 min |

|

|

Precision |

Limited |

Extreme |

|

|

Consumables Needed |

Flux, Solder |

None |

|

|

Skill Requirement |

High |

Moderate (trainable) |

Training and Support from Manufacturers

Top laser welding machine manufacturers in India now offer full support services.

- On-site installation.

- Technical training

- Maintenance packages

- Warranty and Customer Service

These services ensure that jewellers may maximize their investment while minimizing downtime.

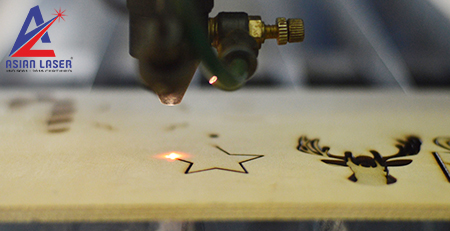

Sustainability and Eco-Friendliness

Laser welding provides a cleaner, more eco-friendly approach.

- less energy-intensive

- emits no toxic fumes or smoke.

- Does away with the need for chemical fluxes

- minimizes the waste of metal and scrap

As more brands shift to sustainable production, implementing such technologies improves brand image and customer trust.

Top Features to Look for When Buying

When comparing jewellery laser welding machines, look for the following features:

- Adjustable pulse duration and power.

- Built-in microscope or camera

- Touchscreen controls.

- High-quality cooling system.

- Foot-pedal operation for convenience

Additionally, you should consider training availability, post-purchase support, and the overall reputation of the brand.

Conclusion:

The demand for high-quality, customized, and swiftly manufactured jewelry is at an all-time high. In this environment, using a jewellery laser welding equipment is more than simply a choice; it is a competitive advantage. The trend toward laser welding is unavoidable, given dropping jewellery laser machine prices, increased equipment availability, and rising consumer expectations.

Jewellers now have access to modern technology that was previously only available to large-scale enterprises, thanks to innovation from India’s laser welding equipment makers. The advantages are too great to overlook, regardless of whether you’re a major manufacturer or an individual designer.

Frequently Asked Questions (FAQ)

1. What is the average jewellery laser welding machine price in India?

The price typically ranges from ₹4.5 lakhs to ₹12 lakhs, depending on the brand, features, and power output.

2. Is laser welding better than traditional soldering for jewellery?

Yes, laser welding provides better clarity, reduced heat distortion, and faster processing. Additionally, it lessens the harm done to fragile parts and stones.

3. Can a beginner operate a jewellery laser welding machine?

The majority of machines have easy-to-use interfaces and need little training. Many manufacturers offer free training with purchase.

4. Are there financing options for small jewellery workshops?

Yes, several laser welding machine manufacturers in India offer EMI options, bank financing, or government subsidies for MSMEs.