Five Tips for Maximizing Your Laser Production

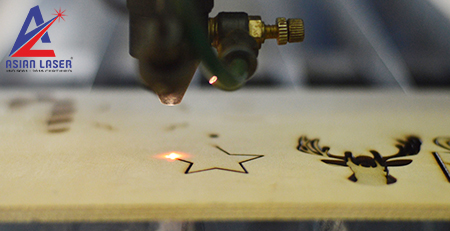

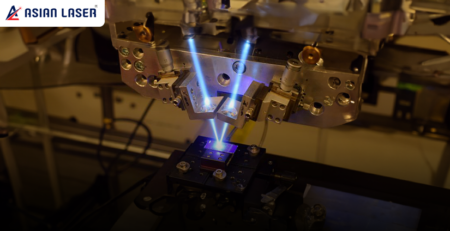

Laser technology has obtained immense demand over the past few years, especially among companies for engraving and cutting. Today, with laser technology, almost any pattern can be etched on numerous materials. Therefore, if you know this procedure and have the finished equipment, you can engrave aspired symbols, patterns or lettering on glass, wood, marble, granite, acrylic, stone, coated metals as well as leather.

The technology is extensively used for etching glass gift items with names and quotes, as well as marking the company’s logos on steel mugs or mementos. Therefore, laser engraving and cutting technology have made it feasible to immediately etch a pattern or cut out even the most complex design. Here are five tips to improve productivity and ensure the best laser results.

- Modify the resolution

Dots per inch (DPI) affect the clarity of the image, and the greater the DPI, the closer together the marked dots are going to be. Higher DPI gives a bright and extremely specific engraved image but may take longer to etch. If you lower the intention, the time taken will also decrease by around 33%. The method is to find the finished combination of resolution and dithering patterns to obtain a great-looking etching design in less time.

- Engrave various items in one batch

The most reliable way to improve productivity is to print in multiples, rather than one at a time. When you are expected to hatch various items of the same design, you can improve your richness by 37% if you print multiples. This can be done by increasing the page size in your graphic composition program to match the full table size of your laser.

- Bottom-up Etching

It is better to start carving from the bottom of the element as you move upwards when printing a mark on any material. This is useful to clean the trash and can be done by adjusting the orientation of the laser etcher for signs before the method.

- Center carving

As compared to setting up design files and jigs, center etching is useful to protect you a lot of time. Center engraving is important to immediately set up custom jobs on an item that needs centered text or graphics. Here the carver can move the laser by hand to the center of the object being etched.

- Excellent Equipment

The quality of the final result and etching speed depends on the kind of equipment used. For this reason, it is advised to invest in the best machines to get the most beneficial results. It is said that equipment with 25-30 watts of power is proper for surfaces like glass, wood, and metals. While for surfaces like natural stone, equipment with more powerful wattage is favored. This means before purchasing any equipment, and it is necessary to consider the elements to be used in the projects.

These are some of the basic tips that you need to know. Laser machines have various purposes in various industries and sectors, which has occurred in its growing popularity. Due to its mounting fame and demand, laser machines continue to look for ways to increase production.