What is the Difference Between Laser Marking and Laser Engraving?

Laser marking and engraving are laser-based processes used for adding marks, patterns, or designs to various materials. While they share some similarities, there are distinct differences in terms of their applications, techniques, and the effects they produce. Let’s explore the key differences between laser marking and laser engraving:

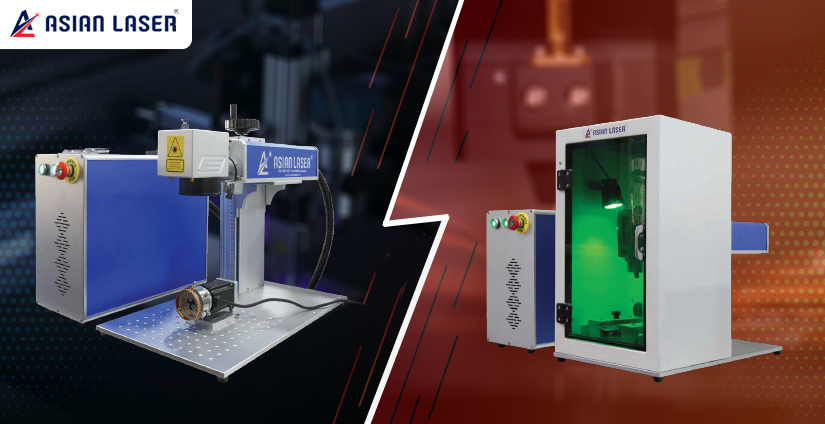

Difference Between Laser Marking & Engraving Machine

-

Depth of Material Removal

Laser Marking

In laser marking, the laser beam interacts with the surface of the material, causing a colour change, discolouration, or a change in texture. However, it does not remove material, and the mark is usually superficial.

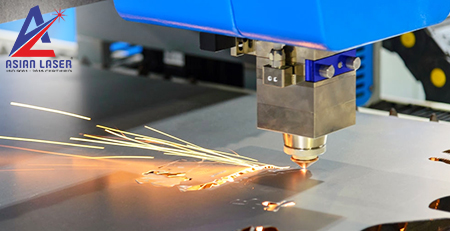

Laser Engraving

Laser engraving involves removing a portion of the material, creating a deeper groove or cavity. The result is a noticeable indentation in the material.

-

Material Alteration

Laser Marking

The primary goal of laser marking is to alter the material’s surface properties without significantly affecting its structure. This method is commonly used for adding serial numbers, barcodes, or logos.

Laser Engraving

Laser engraving alters the physical properties of the material by removing a portion of it. This process is employed when a more pronounced and durable mark is desired.

-

Depth Control

Laser Marking

Marking lasers are designed for precision, and the depth of the mark can be controlled more precisely. This is particularly useful for applications where maintaining the integrity of the material is essential.

Laser Engraving

Engraving lasers are capable of creating deeper marks, providing more flexibility in terms of the desired visual effect and the depth of the design.

-

Speed and Efficiency

Laser Marking

Marking is generally faster than engraving since it doesn’t involve material removal. This makes laser marking suitable for high-speed, high-volume production environments.

Laser Engraving

Engraving, being a material removal process, may take longer depending on the depth and complexity of the design. It is often used for detailed or intricate patterns.

-

Applications

Laser Marking

Common applications include adding identification marks, branding, or decorative patterns on various materials such as metals, plastics, and ceramics.

Laser Engraving

Engraving is often used for creating more profound, more pronounced designs on materials like wood, acrylic, glass, and metals. It is frequently employed in artistic and intricate applications.

-

Material Considerations:

Laser Marking

Suitable for a wide range of materials, including metals, plastics, glass, and some ceramics.

Laser Engraving

It is more versatile and can be applied to a broader spectrum of materials, including those that can withstand the heat generated during the engraving process.

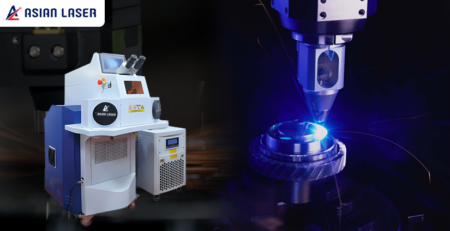

Importance of Laser Marking and Engraving Machines in the Jewellery Industry

Laser marking and engraving machines have become indispensable tools in the jewellery industry, playing a pivotal role in enhancing efficiency, precision, and productivity.

These machines provide unparalleled precision, allowing jewellers to create intricate and detailed designs accurately. This precision is essential for crafting delicate patterns, personalised engravings, and complex filigree work.

Furthermore, these machines offer versatility, enabling jewellers to work with various materials without causing damage. This adaptability is crucial for accommodating diverse jewellery designs and compositions.

Laser Marking Machine Types

Laser marking machines come in various types, each designed to cater to specific applications, materials, and industry requirements. Here are some common varieties of laser marking machines mainly used in the jewellery industry:

-

Fiber Laser Marking Machine:

Applications: Metal and plastic marking, industrial part identification.

Features: Utilises fiber lasers, highly suitable for marking and engraving metals. Offers high precision and speed.

-

CO2 Laser Marking Machine:

Applications: Non-metal materials such as wood, glass, plastics, leather, and some coated metals.

Features: Uses a CO2 laser beam to mark materials by vaporising or discolouring the surface. Ideal for intricate designs and detailed markings.

-

UV Laser Marking Machine:

Applications: Delicate materials, glass, and certain plastics.

Features: Utilises a UV laser beam, suitable for applications where minimal heat is desired. Offers fine marking and is often used in the electronics and medical industries.

Laser Engraving Machine Types

Laser engraving machines come in various types, each tailored to specific materials, applications, and industry needs. Here’s an overview of common types of laser engraving machines:

-

CO2 Laser Engraving Machine:

Applications: Wood, acrylic, leather, glass, plastics, and some metals.

Features: Using a CO2 laser beam to vaporise or remove material creates detailed and precise engravings. Ideal for intricate designs on non-metal materials.

-

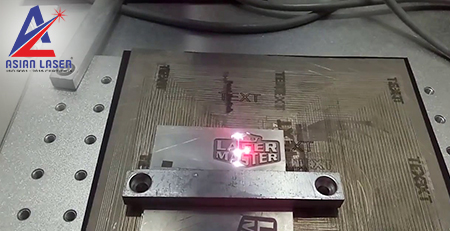

Fiber Laser Engraving Machine:

Applications: Metal and some plastics.

Features: Employs a fiber laser for high-contrast and high-resolution engravings on metals. Well-suited for marking and engraving on a variety of metal surfaces.

-

UV Laser Engraving Machine:

Applications: Delicate materials, glass, certain plastics, and electronics.

Features: Uses a UV laser beam, ideal for high-precision and fine-detail engraving. Suitable for materials that require minimal heat during the engraving process.

To Conclude:

In summary, while both laser marking and engraving machines utilise laser technology to create marks on materials, the key distinction lies in the depth of material removal and the desired outcome.

Laser marking is ideal for surface-level alterations, identification, and fast-paced production. In contrast, laser engraving is chosen when a more profound and visually striking effect is required, often for artistic or detailed applications.

To know more about laser marking and engraving machines, connect with us today.

FAQ

1.What is the primary distinction between laser marking and engraving?

Laser marking alters surface properties, while engraving removes material to create a visible design.

2.How does laser marking differ in terms of depth compared to engraving?

Laser marking creates a superficial, color-changing mark, whereas engraving produces deeper, tactile impressions.

3.Can both processes be used on various materials?

Yes, laser marking is versatile for metals, plastics, and more, while engraving is effective on materials like wood, glass, and metals.

4.Which process is more suitable for intricate designs and fine details?

Laser engraving is preferred for intricate designs, providing finer details due to material removal.

5.Do laser marking and engraving have different applications in industries?

Yes, laser marking is commonly used for product identification, while engraving is chosen for decorative applications and personalized items.