Difference between laser and computerized cutter, why buy a laser machine?

Both mechanical and laser cutting machines are standard forms of production process utilized in the present assembling ventures. But it can be hard to know precisely what both of these machines do. It can be even tougher to figure out the variations and benefits they each have over one another too. These two pieces of appliances are an essential part of day-to-day work that excites many to lay everything out and show-off what makes computerized cutter and laser cutting different.

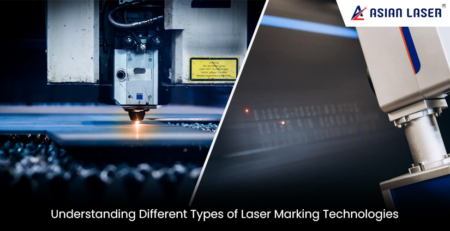

Since laser-cutting machines can cut material as well as apply finish to an item, it tends to have a more streamlined procedure than its mechanical options, which frequently require post-machining medicines. Likewise, there is no immediate contact between the laser gadget and the material, decreasing the opportunity of sullying or unplanned checking. Laser machines additionally make a little warmth influenced zone, which brings down the danger of material twisting or distortion at the cutting site.

CNC, the abbreviation for Computer Numeric Control gadgets, utilizes particular instruments to rapidly and effectively produce items. With CNC cutting, a specialist makes a plan dependent on what the client needs using a product program like CorelDRAW or AutoCAD. When the fashioner feels happy with the drawing, the person puts a bit of metal or some other material on the cutting surface.

Like CNC cutting, a CNC framework manages the laser metal cutting machine. The thing that matters is how the cutting happens. Rather than a cutting device, a laser depends on warmth to make the ideal state of the item. While customary CNC removing cuts the plan, laser cutting depends on a high-vitality light shaft that consumes the metal material.

Laser cutting is an exact warm cutting procedure, using engaged light emission. We frequently suggest this assembling procedure for applications where parts require more resilience. With regards to a particular material decision, we usually work with clients and make proposals dependent on their specific use.

Laser-cutting can be that as it may, be an expensive and testing creation strategy, while boring tool CNC slicing mechanical forms will, in general, be less costly and simpler to coordinate into assembling administrations. Laser gear usually requires a definitive vitality source and expends vitality at a fast pace. This commonly requires a shop to keep up extended battery or capacitor units, notwithstanding conventional force sources. Laser gadgets are frequently costly, and fringe hardware, for example, gold mirrors or zinc selenide windows and focal points, can yield extra costs.

While picking among laser and mechanical cutting, it might be useful to recall that the procedures are not selective of each other and that many machine shops give a mix of the two cutting administrations. Producers gauging the advantages of one sort of cutting versus the other are adjusting laser cutting’s accuracy and dependability against its expenses and vitality utilization, and mechanical cutting’s convenience and cost-effectiveness against its danger of harming or distorting a given material.

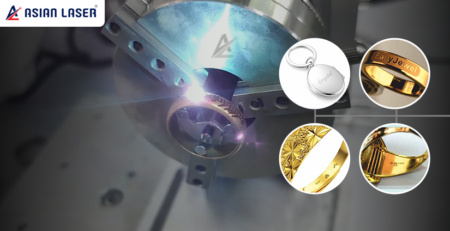

Asian Laser offers advanced engraving, cutting, marking, and industrial laser welding machines in India. We cover the full dynamism series of laser cutting operations, laser welding systems, laser marking scale, texturing machine, heat treatment systems, drilling machines, laser devices, all kinds of support materials, laser processing, and many more laser machining tools.