Laser Marking 101: Everything You Need to Know Before Buying

If you are exploring high-precision, durable, and efficient ways to mark your products, laser marking is a technology you can’t afford to ignore. It’s become the go-to solution for industries ranging from automotive to electronics, packaging to jewelry. At Asian Laser, we’re proud to be one of the most reliable laser marking machine manufacturers in India, offering cutting-edge machines designed for modern industrial needs.

Here’s a complete guide to help you understand laser marking, how it works, and what you should know before buying your own laser marking machine.

What is Laser Marking?

Laser marking is a non-contact process that uses a focused laser beam to create a permanent mark on a wide range of materials. It’s used to add product details such as:

- Serial numbers

- Barcodes

- QR codes

- Company logos

- Expiry dates

- Batch numbers

Unlike traditional marking methods, laser marking delivers long-lasting and tamper-resistant results—without using ink or physical tools.

How Laser Marking Works

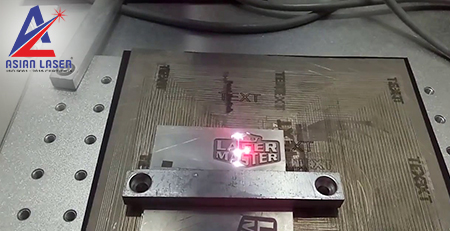

Laser marking works by directing a high-powered beam onto a material’s surface. The energy from the beam alters the surface either by removing material, changing its color, or creating surface texture.

Common laser marking methods include:

- Engraving: Material is vaporized to form deep marks.

- Etching: A lighter surface mark than engraving.

- Annealing: Heat-based marking mainly used on metals, producing a color change without material removal.

- Foaming: Used on plastics, where bubbles are formed in the material.

- Carbon Migration: Creates black marks on metals by bringing carbon to the surface.

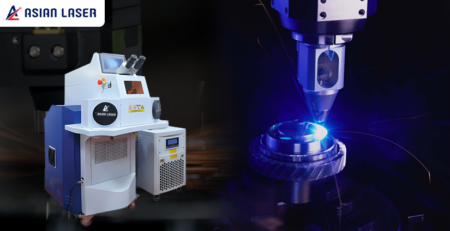

Types of Laser Marking Machines We Offer

At Asian Laser, we manufacture and supply a wide range of laser marking machines to suit different applications:

1. Fiber Laser Marking Machines

Ideal for marking metals such as stainless steel, brass, and aluminum, as well as hard plastics. These machines are perfect for automotive, electronics, and heavy industries.

2. CO₂ Laser Marking Machines

Designed for organic materials like wood, leather, acrylic, paper, and glass. Popular for signage, packaging, and decorative items.

3. UV Laser Marking Machines

Perfect for delicate materials such as medical plastics, silicon, and glass. They provide ultra-fine precision with low heat emission, minimizing damage.

Each of our machines comes with advanced software, precise controls, and customization options to match your production goals.

Materials You Can Mark

Our laser machines are compatible with a wide variety of materials:

- Metals (aluminum, copper, stainless steel)

- Plastics (ABS, PVC, polycarbonate)

- Ceramics and glass

- Paper, cardboard, leather, and wood

Whether you’re marking for identification, branding, or legal compliance, we ensure your marks are permanent, clear, and reliable.

Why Choose Laser Marking?

Laser marking offers multiple benefits over traditional methods like inkjet printing, stamping, or labeling:

- No consumables like ink or chemicals

- Low maintenance and longer lifespan

- High-speed operation and consistent quality

- Eco-friendly, clean, and waste-free

- Precise and detailed markings, even on tiny components

In the long run, a laser marking system is more cost-effective and scalable for any production setup.

Essential Safety Considerations

Laser machines must be operated with care. Most high-powered laser systems are classified as Class 4, meaning:

- Protective eyewear is mandatory during repair and maintenance

- Proper shielding and enclosures are recommended

- Adequate ventilation is needed, especially when marking plastics

We at Asian Laser provide all required safety documentation and training to ensure your team operates each machine safely and confidently.

What to Look for Before Buying a Laser Marking Machine

Buying the right laser marking machine requires clear evaluation of your needs:

- Understand Your Application

Are you marking metals, plastics, or packaging materials? Different materials need different laser types. - Choose the Right Laser Type

Fiber, CO₂, and UV lasers each have unique capabilities. Select the one that fits your product line. - Consider Software and Features

Look for intuitive, powerful software that supports barcode, QR code, and graphic designs. - After-Sales Support

Choose a manufacturer that offers installation, maintenance, and expert support—which is exactly what Asian Laser guarantees.

Industries We Serve

Our machines are trusted across multiple industries, including:

- Automotive

- Electronics

- Aerospace

- FMCG and packaging

- Medical devices

- Jewelry and personal branding

Every solution is tailored to optimize speed, quality, and performance.

Why Asian Laser is the Right Choice

As one of the leading laser marking machine manufacturers in India, Asian Laser is dedicated to delivering:

- Customized marking machines for unique applications

- Advanced technology with user-friendly controls

- Reliable service and nationwide support

- Competitive pricing without compromising quality

We don’t just sell machines—we build long-term partnerships.

Conclusion

Investing in a laser marking machine is a step toward improved quality, brand visibility, and operational efficiency. With so many options in the market, choosing the right manufacturer makes all the difference. As one of the most trusted laser marking machine manufacturers in India, Asian Laser is here to guide you every step of the way.

From helping you choose the right model to offering post-sale support and training, we ensure your marking process is seamless, efficient, and future-proof.

Ready to take the next step?

Contact us today for expert guidance and a free consultation..

Frequently Asked Questions (FAQs)

- What is the difference between laser marking, engraving, and etching?

Laser marking changes the surface, engraving removes material deeply, and etching creates shallow marks. - Which industries use laser marking machines?

Industries like automotive, electronics, medical, FMCG, and jewelry commonly use laser marking. - What materials can be marked using laser marking machines?

Metals, plastics, glass, ceramics, wood, leather, and more can be marked with our machines. - Is laser marking safe to use in a factory or workshop?

Yes, with safety gear, enclosures, and proper ventilation, laser marking is safe to use. - Why should I choose Asian Laser over other manufacturers?

We offer reliable machines, expert support, customization, and strong after-sales service across India.