Four best mould repair products at lower costs and better quality

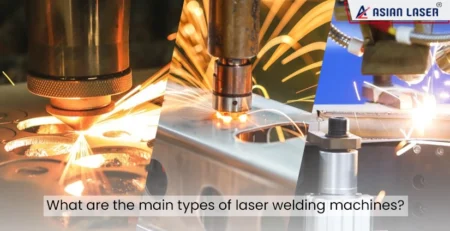

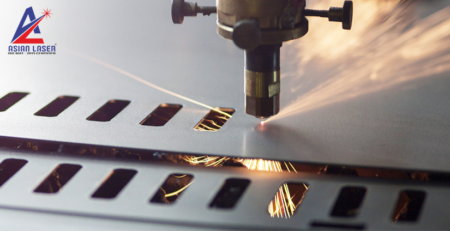

The modest precision welding shops of today specializing in the plastic injection mould, die, and tooling repair have an extended range of innovative technologies available to improve their capability to render the highest level of craftsmanship, quality, and service to their clients. One of the rapidly growing technologies is the utilization of manual laser micro-welding systems as an alternative to conventional microscope Gas Tungsten Arc (GTA) welding.

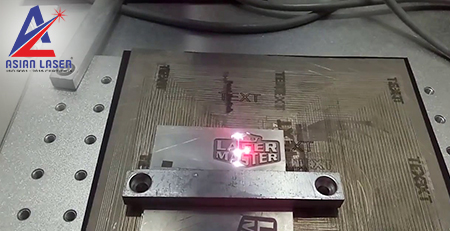

We at Asian Laser manufacture machines that excel in the process of mould repair and possess best-in-class attributes. Our leading products in mould repair are namely:

Mould Repairing Dual Type ALCC 300

In this crane-type laser welding machine, the buyer will receive a crane that will be equipped within the welding machine. This machinery is close-packed and capable of fitting in small spaces.

Key features:

- Less heat-affected zone.

- No deformation of a product.

- Deep and firm welding.

- 24 hrs of continuous work.

- Melt fully without trachoma.

- Compact.

Mould Repairing with Crane ALC 300

The crane-type mould laser welding machines are accessible in two powers 300W and 600W. This precise piece of machinery from Asian Laser can serve customers with laser processing equipment and processing solution as well. This welding machine comes with a crane.

Key features:

- Less heat-affected zone.

- No deformation of a product.

- Deep and firm welding.

- 24 hrs of continuous work.

- Melt fully without trachoma.

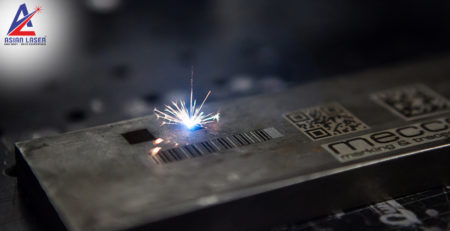

Mould Repairing Standard ALS 300

This machine is mainly designed for mould industries, utilized to repair precision mould. This technology can also be used to modify the design of the mould and help in reducing development time. The Mould Repair Laser Welding Machine by Asian Laser can improve the mould in-house with unmatched precision and speed. It’s economical and helps in saving time.

Key features:

- Less heat-affected zone.

- No deformation of a product.

- Deep and firm welding.

- 24 hrs of continuous work.

- Melt fully without trachoma.

Mould Repairing Standard Dual Type ALDH 400

This new standard laser welding machine at Asian Laser is an example of how innovation and use of advanced processes allow ambitious production for various industries helping save multiple resources. Such methods result in reputably high-performance and lightweight products for the manufacturers. This machine also being compact, occupies substantially less space.

Key features:

- Multiple-time repairability for moulds.

- Less heat-affected zone.

- No deformation of the product.

- Deep and firm welding.

- Melt fully without trachoma.

- 24 hours of continuous work.

Industries

All these machines have been specially developed to serve the requirements of the given industries:

- Automotive

- Solar

- Electronics

- Healthcare

- Hardware

- Watches

- Stainless steel

- Denture/Dentistry

- Jewellery

Most of these tools can be repaired multiple times. This factor alone has substantial financial benefits for the owner of the machine. An advantage for both the repair shop and its customers is that laser welding is more precise and assists in keeping the repair process short, limiting the damage to surrounding areas of the weld only. This precision minimizes machining and time for rework as there is less weld to remove. Whether you repair moulds as a service or business or have a tool shop that does it in-house, this is a technology to examine. It will undoubtedly make your business more competitive and save a lot of precious time and money in the long run.

Asian Laser is amongst the best cutting, engraving, and laser welding companies in India. We incorporate the full dynamism series of laser cutting operations, laser welding systems, Laser marking scale, Laser texturing machine, laser heat treatment systems, laser drilling machines, laser devices, all kinds of support materials, laser processing, and plasma machining tools.