Top Features of the Jewellery Laser Deep Engraving & Cutting Machine ALX 50

In today’s jewellery world, where detail is everything and personalization is in high demand, having the right tools can truly make or break a workshop. One machine that’s quietly gaining recognition in serious jewellery circles is the Laser Deep Engraving & Cutting Machine ALX 50. And no, it’s not just a flashy piece of tech; it’s something that’s reshaping how jewellers work with metals, designs, and time.

Having spoken with small business owners, bench jewellers, and even educators in the field, it’s clear that this machine is a workhorse packed into a compact, surprisingly intuitive package. If you’re curious about what makes it special, let’s break it down.

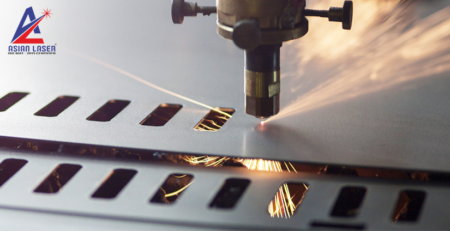

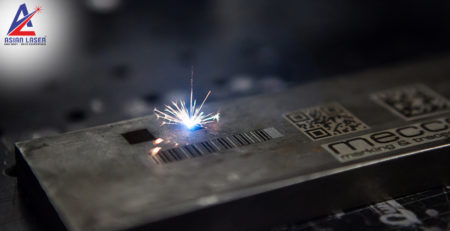

It Actually Cuts, Not Just Scratches

Most basic engraving tools scratch the surface, leaving markings that can fade over time or disappear with wear. The ALX 50 takes it to another level. We’re talking about real depth engraving, where letters, logos, or serial numbers are deeply embedded into the metal. These aren’t going anywhere, even with polishing.

This is crucial for high-value pieces where longevity and authenticity matter. If you’re engraving a client’s initials onto a ring or marking your brand onto a necklace, the results stay sharp for life.

Precision That Makes Intricate Work Possible

Jewellers are artists, and like any artist, the right brush, or in this case, beam, matters. The ALX 50 uses a focused laser beam with pinpoint accuracy. It can trace fine lines, delicate curves, and complicated shapes that are almost impossible to achieve by hand or with older machines.

Designers I’ve spoken to love this machine because it doesn’t limit their creativity. Whether it’s a detailed floral pattern on a bracelet or a custom lattice cut-out on a pendant, it delivers what the mind imagines.

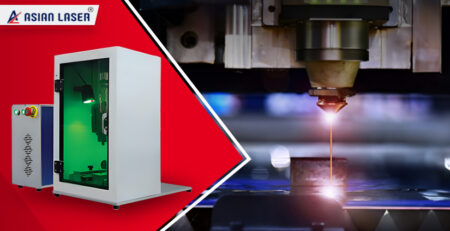

It’s Designed for Real-World Workshops

Let’s be honest, jewelry benches are often short on space. The ALX 50 doesn’t demand a dedicated room or massive counter space. It’s compact enough to fit into most studios and yet strong enough to run batch jobs day after day.

It’s also made with a solid outer frame. You can feel that it’s built for the long haul. This isn’t one of those machines that looks great in a catalogue and falls apart after a few weeks. It’s a tool built for actual working jewellers.

You Don’t Need to Be a Tech Guru

I’ve personally seen people over 60, who’ve never touched design software before, learn to use this machine in an afternoon. That’s because the interface is clean, touchscreen-based, and intuitive. Upload your design, select your material, adjust a few simple settings, and you’re off.

This is perfect for small studios where the same person is designing, engraving, and serving the client. It’s a smart machine that doesn’t make you feel dumb.

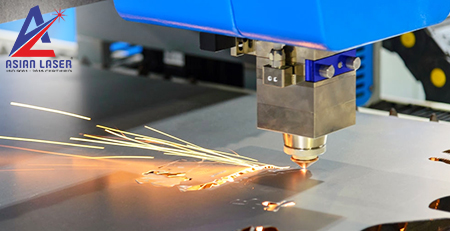

No Heat Damage, No Ugly Edges

Traditional cutting methods or older laser systems often leave burnt edges, discoloration, or tiny heat warps. The ALX 50 is built to avoid that. It uses pulse control technology, which means it applies just enough heat to cut or engrave, but not enough to affect nearby areas or change the finish.

That’s especially important if you’re working near stones, enamel, or sensitive metals like platinum.

It Handles More Than Just Gold and Silver

One of the features that makes this machine stand out is material flexibility. You’re not limited to one or two metal types. The ALX 50 works smoothly on:

- Gold (yellow, white, rose)

- Silver

- Platinum

- Stainless steel

- Titanium

And even some non-metals, like specific plastics

This opens the door for more experimentation, whether that’s creating branded keychains, personalized dog tags, or unusual multi-metal jewellery combinations.

Fume-Free and Enclosed for Safety

This one might sound boring, but it’s actually a huge benefit: the machine is enclosed, which means fumes, dust, and laser reflections are contained. There’s also a fume extractor externally connected.

If you’re running a retail-front studio, this matters. It’s safe to operate while clients are around, and it keeps your workspace clean; no more worrying about metal dust flying around or needing protective goggles at all times.

Great for One-Offs or Batch Runs

If you make only one ring at a time, great, this machine can handle it. But what if you get a wholesale order of 50 personalized bangles or nameplate pendants? No problem.

The ALX 50 lets you save settings and design templates, so you can load the exact same engraving job multiple times with the same results. It’s ideal for small brands scaling up or jewellers working with wedding parties, gifting clients, or seasonal demand.

You Can Adjust the Beam Size

This is a subtle feature, but a useful one: the ALX 50 lets you change the beam width depending on what you’re doing. Want bold, chunky initials? Widen the beam. Need micro-level detail on a 5 mm charm? Narrow it down. You get full control over how the result looks and feels, instead of being locked into a default setting.

It Speaks the Language of Today’s Jewellery Industry

Whether you’re just starting out or you’ve been in the business for 20 years, one thing is clear: the market now expects customization. Clients want their names, their kids’ initials, and their wedding dates engraved cleanly, quickly, and permanently.

This machine gives you the confidence to say yes to those requests, without outsourcing or guessing whether it’ll come out right.

Final Thoughts

If you’ve been in this industry long enough, you know that not every tool lives up to its brochure. But the Laser Deep Engraving & Cutting Machine ALX 50 genuinely earns its place in a serious jeweller’s setup.