The Advantages of Using Laser Welding Machines in Industrial Applications

In the present fast-paced industrial landscape, efficiency and precision are paramount. Industrial processes need advanced machinery that can provide high-quality results rapidly and reliably. Laser welding is one such technology that has transformed industrial welding. There are very few industrial laser welding machine manufacturers in India with numerous benefits of integrating laser welding machines into industrial applications.

Precision at Its Finest

Precision is paramount when welding intricate components or working with delicate materials. To achieve this level of accuracy, you need to know the best supplier of industrial laser welding machines in Mumbai. Laser welding machines are preferred over traditional welding methods because of the focused beams of intense light they use. Unlike conventional welding methods, which can cause distortion or damage to nearby components, laser welding offers pinpoint accuracy, ensuring that only the intended area is precisely fused without affecting surrounding materials.

Enhanced Speed and Efficiency

Time is money in the industrial sector and every minute counts. Laser welding machines boast remarkable speed and efficiency, significantly reducing welding times compared to conventional methods. This acceleration in the welding process translates to increased productivity and shorter lead times, allowing manufacturers to meet tight deadlines and fulfil orders promptly.

Versatility Across Various Materials

One of the standout features of laser welding machines is their versatility in welding a wide range of materials. Laser welding can easily handle them all, whether it’s stainless steel, aluminium, titanium, or even exotic alloys. This versatility makes laser welding attractive for automotive, aerospace, electronics, medical devices, and more industries.

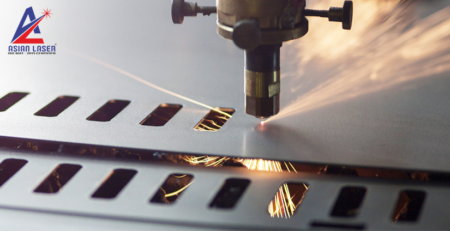

Minimal Heat Affected Zone

Heat management is a critical consideration in welding, as excessive heat can lead to undesirable consequences such as warping, distortion, or metallurgical changes in the material. Laser welding mitigates this issue by producing a minimal heat-affected zone. The concentrated heat from the laser beam results in localized heating, minimizing thermal distortion and preserving the integrity of the surrounding area.

Clean and Precise Welds

In industrial applications where aesthetics and quality are paramount, laser welding shines. The process produces clean, precise welds with minimal spatter or splatter, resulting in a visually appealing finish. This is particularly advantageous in automotive manufacturing or consumer electronics industries, where the final product’s appearance is as important as its functionality.

Cost-Effective Solutions

While the initial investment in laser welding machines may seem substantial, the long-term benefits outweigh the costs. The enhanced speed, efficiency, and quality of laser welding translate to cost savings that are beneficial in India over time. Reduced rework, lower material waste, and increased productivity contribute to significant cost-effectiveness, making laser welding a wise investment for forward-thinking manufacturers.

Environmental Friendliness

In an era where sustainability is a top priority for many industries, laser welding is an environmentally friendly option. Unlike traditional welding methods that may involve using consumables such as filler materials or shielding gases, laser welding is a clean process that minimizes waste and emissions. This aligns with the growing emphasis on green manufacturing practices and corporate social responsibility.

Conclusion

Adopting laser welding machines in industrial applications can provide numerous advantages, including precision, speed, versatility, and cost-effectiveness. Manufacturers who wish to remain competitive in today’s market can greatly benefit from incorporating this advanced technology into their production processes. Laser welding has the potential to deliver superior results with minimal drawbacks, making it a game-changer in industrial manufacturing. In conclusion, laser welding is undoubtedly a valuable addition to industrial manufacturing.