How To Choose The Right Laser Engraving Machine?

Laser engraving machines have transformed the world of engraving, offering precision, versatility, and efficiency for a wide range of applications. Whether you’re a hobbyist, all business owner, or industrial manufacturer, selecting the suitable laser engraving machine is crucial for achieving optimal results.

With a wide range of options available in the industry, navigating through the selection process can be daunting. Our guide provides essential factors to consider when choosing the best laser engraving machine for all businesses.

Guide To Select The Best Engraving Machine For all Business

-

Define Your Requirements

Before diving into the myriad options available, clearly defining your requirements is essential. Consider factors such as the materials you’ll be working with, the size and intricacy of the designs you intend to engrave, production volume, and budget constraints.

Understanding your specific needs will help narrow the options. Hence, making it easy for you to choose a machine that aligns with your objectives.

-

Types of Laser Engraving Machines

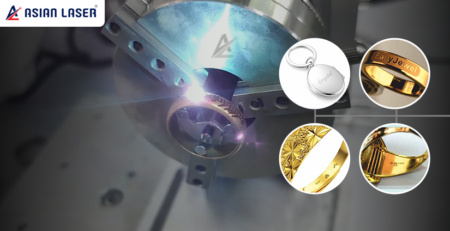

There are primarily three types of laser engraving machines, namely CO2 lasers, fiber lasers, and diode lasers. CO2 lasers are ideal for engraving on organic materials like wood, acrylic, and leather, while fiber lasers excel at engraving metals and certain plastics.

Diode lasers are suitable for smaller, low-power applications such as engraving on smartphones and jewellery. Selecting the correct type of laser depends on the materials you’ll be engraving and the desired outcome.

-

Power and Speed Requirements

The power and speed of a laser engraving machine significantly impact its capabilities and productivity. Higher wattage lasers offer greater cutting and engraving depths, allowing you to work with thicker materials and achieve faster processing speeds. However, higher power typically comes with a higher price tag.

Assess your production requirements and balance them with your budget to determine your machine’s optimal power and speed specifications. For instance, our Desktop Laser Engraving Machine provides optimal power to work 24 hours a day, non-stop.

-

Bed Size and Engraving Area

The size of the engraving bed indicates the dimensions of the materials you can work with. It’s imperative to consider the size of the items you’ll be engraving and ensure the machine’s bed size accommodates your needs. It’s also important to factor in the available workspace in your facility to ensure the machine fits comfortably within the designated area.

-

Software Compatibility and Ease of Use

The software accompanying the laser engraving machine plays a critical role in its functionality and user experience. Look for machines compatible with industry-standard design software such as Adobe Illustrator, CorelDRAW, or AutoCAD.

Additionally, consider the user interface of the machine’s control software and ensure it’s intuitive and user-friendly, especially if you’re a beginner or have limited experience with laser engraving technology.

-

Reliability, Durability, and Support

Investing in a desktop laser engraving machine is an important decision, and choosing a reliable and durable product backed by excellent customer support is essential. Research the manufacturer’s reputation and track record, read reviews from other users, and inquire about warranty coverage and after-sales support services.

A reputable company with a proven record of delivering quality products and reliable customer support will provide peace of mind.

Why Choose Asian Laser For Buying Desktop Engraving Machines?

In the realm of laser engraving machines, Asian Laser stands out as a leading provider with a reputation for quality, reliability, and innovation. With a commitment to delivering robust technology and exceptional customer service, Asian Laser offers numerous compelling reasons why it should be your top choice when purchasing a laser engraving machine.

Unmatched Expertise and Experience:

Asian Laser boasts extensive expertise and experience in the laser engraving industry. With years of research and development, they have honed their craft and perfected their machines to meet the expectations of customers across various industries.

Our team of skilled engineers and technicians continually strive for excellence, ensuring that every machine meets the highest standards of quality and performance.

Wide Range of Products

Asian Laser offers a comprehensive range of laser engraving machines tailored to suit different applications and industries. Whether you’re engraving on wood, metal, acrylic, leather, or other materials, Asian Laser has a solution to meet your needs.

Our diverse product lineup includes entry-level desktop models and high-powered industrial systems, catering to customers of all sizes and requirements.

Customization Options

Asian Laser understands every customer has unique requirements, which is why we offer customization options to tailor their machines to specific needs. Whether adjusting power and speed settings, integrating specialized accessories, or designing custom fixtures, our team works closely with customers to create bespoke solutions.

Exceptional Customer Service and Support

Customer satisfaction is paramount at Asian Laser, and they go above and beyond to provide exceptional service and support to their customers. From pre-sales consultation and machine selection to installation, training, and making people understand how laser engraving machines work, our dedicated team of professionals ensures you have a seamless experience from start to finish.

Whether you have questions or issues or require maintenance, Asian Laser is here to support you.

To Conclude:

Choosing a suitable laser engraving machine requires careful consideration of your specific requirements, budget constraints, and production objectives.

By defining your needs, understanding the different types of laser engraving machines, evaluating power and speed specifications, assessing bed size and engraving area, and selecting the perfect machine to meet your engraving needs.