Application of Jewellery Laser Welding Machine ALFL 75

Introduction

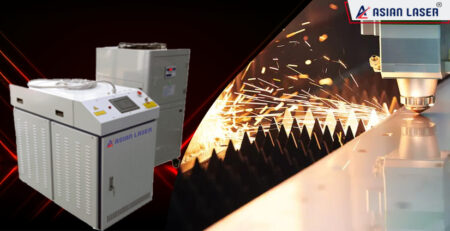

In the fast-paced world of jewellery manufacturing, innovation and precision are crucial for standing out. One such game-changing innovation is the Jewellery Laser Welding Machine ALFL 75, developed by Asian Laser, a leading name in laser technology. This high-performance welding machine has revolutionized the way jewellers craft, repair, and customize fine jewellery. By offering exceptional accuracy, minimal thermal distortion, and time-saving operation, the ALFL 75 is becoming a staple in workshops across India.

This blog will explore the wide-ranging applications of the Jewellery Laser Welding Machine ALFL 75, while also examining how it compares with other jewellery laser machines, discussing the jewellery laser welding machine price in India, and evaluating whether it’s worth the investment for your business.

What is the Jewellery Laser Welding Machine ALFL 75?

The Jewellery Laser Welding Machine ALFL 75 is a high-precision tool specifically designed for welding fine jewellery components with minimum heat input. It uses focused laser beams to join metals at a microscopic level without damaging surrounding stones or delicate materials. The 75 in the model name typically denotes the machine’s wattage or energy capacity, making it suitable for both small and medium-scale operations.

Key Features:

- Totally maintenance free machine

- Specially designed for showrooms

- A laser beam with high-precision

- Adjustable energy, pulse width, and frequency

- Minimal thermal distortion

- Suitable for gold, silver, platinum, and other precious metals

- A user-friendly interface with touch-screen controls

Core Applications of the Jewellery Laser Welding Machine ALFL 75

1. Repairing Fine Jewellery

Conventional restoration methods frequently run the danger of breaking valuable diamonds or settings. The ALFL 75 allows for non-invasive repairs such as re-tipping prongs, closing minor cracks, and mending chains, all while retaining the structural and look quality of the item.

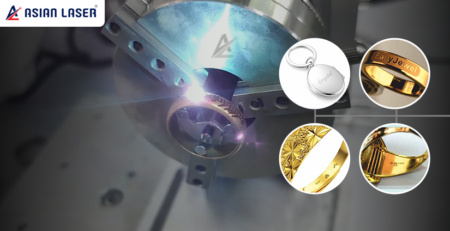

2. Assembling Intricate Designs

Artisans can use this machine to assemble complex parts of a jewellery piece with microscopic accuracy. The ALFL 75 makes it possible to create intricate filigree designs, multi-component pendants, and customized jewellery with seamless joints.

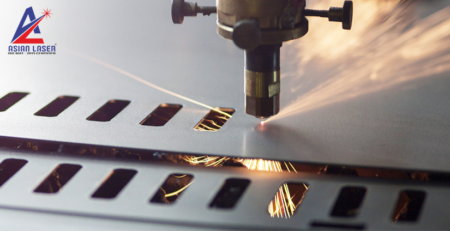

3. Welding Near Gemstones

Unlike traditional soldering, the Jewellery Laser Welding Machine ALFL 75 generates localized heat. This allows for safe welding near temperature-sensitive gemstones, eliminating the need to remove stones before repair or alteration.

4. Customizing Jewellery

The ALFL 75 facilitates easy customization by enabling precise alterations. Whether resizing rings or modifying clasp settings, the machine makes it possible with minimum effort and no risk of metal discoloration.

5. Micro Welding for Watches

In addition to jewellery, this machine is widely used in the repair and assembly of luxury watches. Its high precision and control make it ideal for micro-welding watch components, improving both functionality and appearance.

Benefits Over Traditional Jewellery Welding Techniques

Greater Precision

Laser welding is more accurate than manual soldering. Jewelers may deal with tight tanes with the ALFL 75, guaranteeing excellent quality and fit.

Minimal Heat Impact

The machine concentrates energy in a confined spot, minimizing the risk of warping or damaging the surrounding area a major benefit when working with heat-sensitive pieces.

Cleaner Finish

Laser welding produces smooth, clean joints without excessive oxidation, reducing the need for post-processing like polishing and cleaning.

Time Efficiency

With rapid setup and operation, jewellers can complete complex tasks in minutes instead of hours, boosting overall workshop productivity.

Jewellery Laser Welding Machine Price in India

The jewellery laser welding machine price in India varies based on specifications, brand reputation, and service support. As of 2025:

- Entry-level machines: ₹4,00,000 to ₹6,00,000

- Mid-range models like ALFL 75: ₹5,00,000 to ₹9,00,000

- High-end models with advanced features: ₹10,00,000+

While the Jewellery Laser Welding Machine ALFL 75 may appear costly initially, its return on investment is significant due to enhanced quality, reduced wastage, and higher customer satisfaction.

Comparing with Other Jewellery Laser Machines

| Feature | ALFL 75 | Other Mid-Range Machines | Entry-Level Machines |

| Wattage | 75W | 60–70W | 40–50W |

| Precision | High | Moderate | Low |

| Ease of Use | Touchscreen Interface | Basic Controls | Manual |

| Price | ₹5.5–9 Lakh | ₹5–7 Lakh | ₹3–5 Lakh |

| Suitable Metals | All Precious Metals | Selective | Limited |

The Jewellery Laser Welding Machine ALFL 75 stands out due to its balance of power, control, and affordability, making it ideal for professional jewellery workshops aiming to scale up operations.

Things to Consider Before Buying a Jewellery Laser Welding Machine

Technical Support

Always opt for a supplier that offers installation, training, and after-sales support to avoid downtime.

Power Requirements

Make sure your workshop can support the voltage and power settings required for efficient machine operation.

Warranty & Brand Reliability

Check for warranty terms and brand credibility to ensure long-term reliability.

Precision & Compatibility

Choose a model compatible with the types of metals and designs you commonly work with.

Jewellery Laser Machine Price: What Justifies the Cost?

- High-precision output

- Reduced material waste

- Lower labour cost

- Fewer post-welding processes

- Customer satisfaction through flawless finishes

These elements add to the jewellry laser machine’s effective high cost, yet the equipment soon makes up for its cost through increased product value and operational savings.

Why ALFL 75 is the Future of Jewellery Manufacturing

The ALFL 75 Jewellery Laser Welding Machine has the potential to completely transform jewellry production in the future due to the rising need for accuracy, personalization, and environmentally friendly production. Whether you’re working on delicate gold or long-lasting platinum settings, the ALFL 75 provides unparalleled control and precision. This jewellry laser welding manufacturing machine in India, which was created to satisfy the demands faced by modern jewelers, encourages manufacturers to explore the limits of creativity while maintaining strict durability and finish standards. New standards for speed, efficiency, and environmentally conscious manufacturing are being set by advanced technologies like the ALFL 75 as the industry develops.

Conclusion

Investing in a Jewellery Laser Welding Machine ALFL 75 is not just about adopting new technology it’s about elevating craftsmanship, ensuring customer satisfaction, and staying competitive in a rapidly evolving market. From small repair shops to large-scale manufacturers, this machine is a game-changer in every sense.

While the jewellery laser welding machine price in India may initially look like a heavy investment, the long-term benefits in quality, efficiency, and customer loyalty far outweigh the cost. Whether you are entering the market or upgrading your existing tools, the ALFL 75 is an intelligent and future-ready choice.

Frequently Asked Questions (FAQs)

1. What is the Jewellery Laser Welding Machine ALFL 75 used for?

The Jewellery Laser Welding Machine ALFL 75 is primarily used for precision welding of jewellery components. It allows for repairs, resizing, assembly of intricate designs, and micro-welding without affecting heat-sensitive stones or delicate structures.

2. What types of metals can the ALFL 75 weld?

The ALFL 75 is suitable for a wide range of precious and semi-precious metals including gold, silver, platinum, palladium, and titanium. It is also capable of working with various Metals used in jewellery making.

3. What distinguishes the ALFL 75 from conventional soldering techniques?

The ALFL 75 provides precise accuracy, low heat impact, and eliminates the need for filler or flux materials. It guarantees cleaner joints, a better polish, and the preservation of adjacent stones and materials, in contrast to traditional soldering.

4. Can the ALFL 75 be used for watch repairs as well?

Yes, its micro-welding capability makes it ideal for fine watch repairs, especially for components that require high precision and minimum distortion.