What are the 5 common mistakes in Laser Engraving and how to avoid them

Mistakes and errors are a human tendency and are committed by every individual in different walks of life. However, there are some common mistakes that are a result of lack of understanding. Such mistakes usually happen while using inanimate objects like machines for regular operations.

Machines comprise of complex mechanisms that can be hard to comprehend. Even, qualified engineers sometimes fail to understand the various functions that a machine can offer. On the other hand, laser machines are way more complicated than normal machines in terms of functionality and operations.

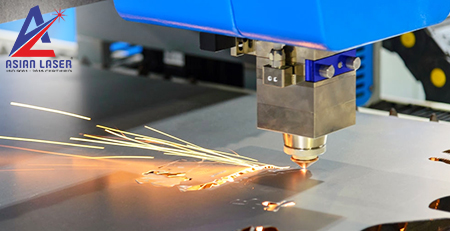

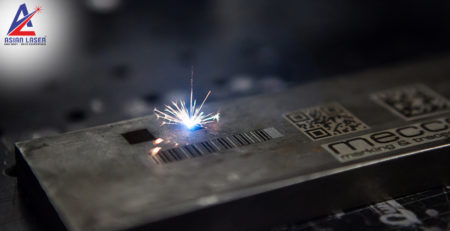

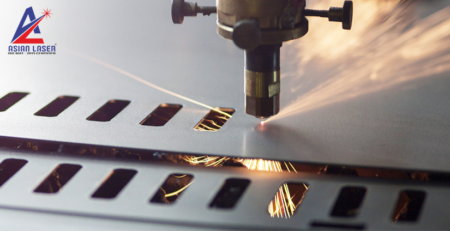

Laser machines are used for various commercial applications these days. They are widely preferred due to their speed, accuracy and functionality. The possibilities of customized creation with these machines can be endless. However, a lack of understanding of these machines can lead to mistakes that can be harmful for business and people operating them.

Here are some common mistakes that can be avoided while using laser engraving machines:

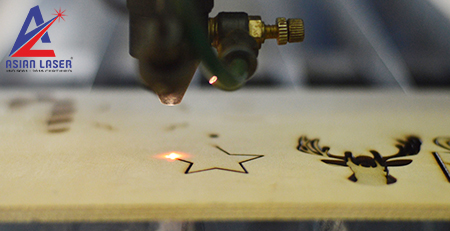

- Burning through the Fabric: When handling a laser engraving machine it is important to understand its abilities and output capacity first. A vast majority of people who handle engraving machines often burn through materials such as fabric and plastic. To operate engraving machines on fabric surfaces, the machine should be calibrated to the right amount of heat emission. Rich or thick fabrics such as denim, leather and canvas can withstand high-temperature setting during engraving. However, when it comes to delicate fabrics such as silk, nylon and cotton the heat setting needs to be adjusted according to the density of the cloth. To avoid burning through delicate fabrics it is recommended that the laser is tested on a spare fabric with a configuration of 100% speed and low beam power of 5% to 10%. The power and speed of the machine can be adjusted to get the desired results.

- Unable to create the frosty effect on acrylics: Acrylics with appealing graphics prints are widely preferred worldwide but printing these appealing graphics on acrylic surfaces can be challenging.

There are two types of acrylic surfaces that are used for industrial operations 1. Cast acrylic- a form of liquid that is poured on to the moulds to create different shapes and sizes. It is suitable for engraving as it automatically turns into a frosty white colour when engraved. 2. Extruded acrylics: is an inexpensive option when compared to cast acrylic as it is formed through a higher-volume manufacturing method. However, this type of acrylic may not be able to produce a frosty appearance. On the other hand, when engraved, extruded acrylics give an embossed look.

- Glass engraving: Glass engraving is a common phenomenon and one of the commonly used methods of customization. Considering the fact that glass is a fragile material, engraving with the wrong configuration can result in substantial losses. However, there are some tips and settings that can be followed to get the perfect engraving results.

- The use of a lower resolution, around 300 DPI, can produce a better result on the glass.

- Changing the black in the image to 80% black.

- Applying a thin, wet sheet of paper or a paper towel around the engraving area can make the engraving process smoother.

- Applying liquid soap to the glass’s surface can reduce heat dissipation and produce clearer engravings.

- If there are pieces of shattered glass after the engraving, polishing with a non-scratch scour pad can improve the engraving.

Engraving machines can work wonders for businesses if used properly. Therefore, we at Asian Laser ensure that our customers are well-educated about the functions of the machines by our expert installation guides. For more information on engraving machines, you can visit our website.